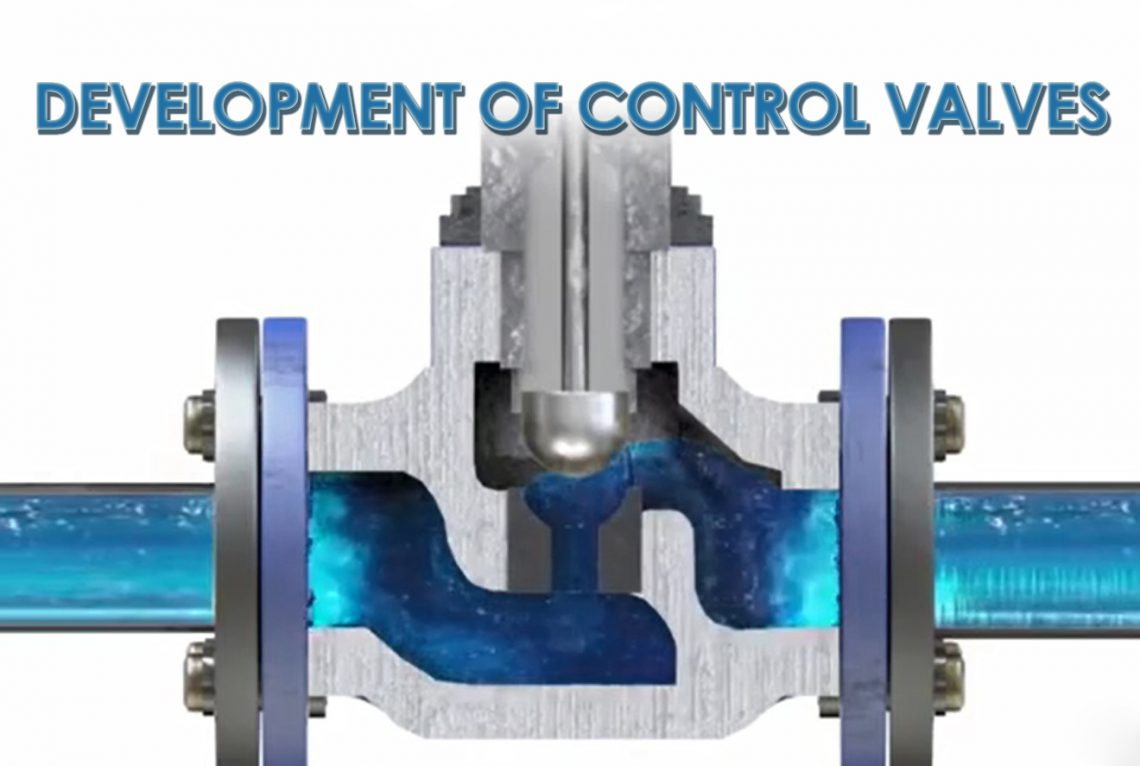

Regulating valve, or control valve, refers to a tool used in industrial production to adjust process parameters such as medium flow, pressure, temperature, liquid level, etc. In some automated production links, the opening of the valve can be automatically adjusted according to the control signal in the system, so as to realize the adjustment of medium flow, pressure, temperature, and liquid level.

Development History

Since the beginning of the 20th century, the development of control valves has produced ten categories of control valve products, self-operated valves and positioners. The specific timeline is as follows:

The 1920s: The original regulating valve for pressure stabilization was introduced.

The 1930s: The V-type regulating ball valve came out, and the representative products are double-seat valves and single-seat valves with “V”-shaped notch.

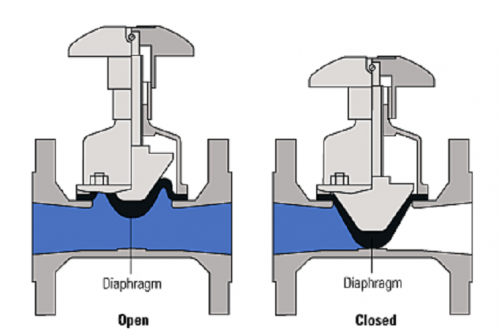

The 1940s: The emergence of positioners further produces new varieties of regulating valves, such as diaphragm valves, angle valves, butterfly valves, ball valves, etc.

The 1950s: The ball valve has been widely used, and the three-way valve has been put into the pipeline system to substitute two single-seat valves.

The 1960s: The eighth structure of the regulating valve – the sleeve valve was introduced.

The 1970s: The ninth type of regulating valve – the eccentric rotary valve came out.

The 1980s: During this period, a major development was to improve the structure of the fine and small regulating valve, changing the single-spring pneumatic diaphragm actuator to a multi-spring diaphragm actuator. The salient features of this modification are a 30% reduction in the weight and height of the regulating valve and a 30% increase in the flow coefficient.

The 1990s: The focus of regulating valves in the 1990s was on the research, improvement and improvement of reliability and special and difficult products. In addition, a tenth configuration of the product, a full-featured ultra-light valve, was introduced. Its outstanding features are breakthroughs in reliability, functionality and weight.

Future Development

The development direction of the control valve is mainly intelligent, standardization, miniaturization, rotation and safety.

The purpose of intelligence is to simplify the operation difficulty of the control valve, which is mainly manifested in 1) intelligent functions such as self-diagnosis of the control valve and remote communication of operating status; 2) reducing product types and simplifying the production process; 3) digital communication; 4) smart valve positioner.

The purpose of standardization is to align all aspects of the regulating valve, making it easier and more convenient for users to purchase, use and maintain. Standardization is mainly manifested in 1) interchangeability; 2) interoperability; 3) standardized diagnostic software and other auxiliary software; 4) standardized selection procedures.

The purpose of miniaturization is to reduce the weight of the valve, making it easier to transport, install and maintain. The miniaturization of the control valve is mainly achieved by the following methods: 1) adopting a fine and small actuator, such as using lightweight materials; 2) changing the flow path structure; 3) using an electric actuator structure.

Rotation refers to the application of more rotary control valves, such as ball valves, in the future. This type of valve is characterized by relatively small volume, small flow resistance, large sealing, and good anti-blocking performance.

The safety of valves will also receive more attention in the future. This is mainly manifested in: 1) The requirements for fault information diagnosis and processing are increased; 2) For the regulating valve of the emergency stop system or safety interlock system, the requirements for timely, reliable and safe activities are put forward to ensure that they are responsive and accurate; 3. For regulating valves used in dangerous occasions, the certification procedures should be simplified; 4) Fire protection technology, increased safety technology, intrinsically safe technology, non-sparking technology, etc. are used to ensure the safety of the regulating valve.

The development of high-tech science and technology such as computer science, control theory, and automation has greatly promoted the development of control valves. In the future, the application of control valves will become more and more extensive. For more information about high-quality sanitary control valves, please visit https://www.adamantvalves.com/.