Importance of Pressure Relief Valve

The Pressure Relief Valve is one of the most important types of safety valves. This type of valve sets a limit on the rise of pressure within a hydraulic line. In normal operations, the valve is closed and no fluid passes through; but if the pressure in the line exceeds the limit, the valve opens to relieve the pressure. This protects expensive machinery such as motors pumps and actuators from becoming damaged from high-pressure. Without a relief valve, the pressure can continue to grow until another component fails and pressure is released.

Categories of Pressure Relief Valve

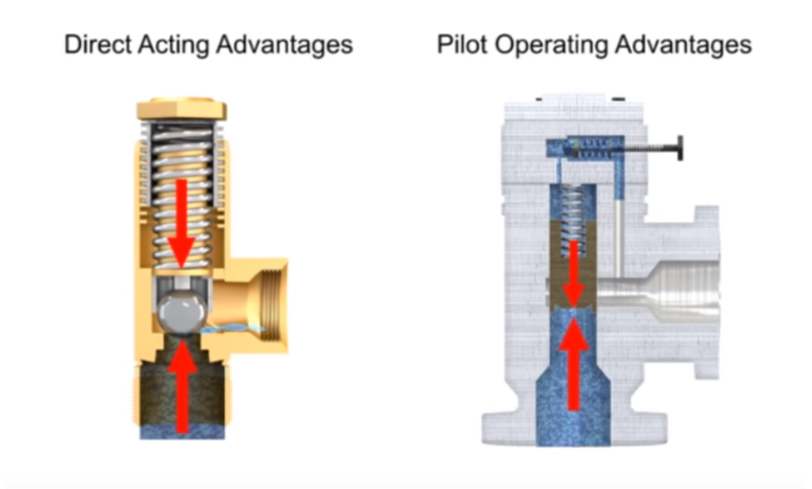

Pressure relief valves fall into two categories: direct acting or pilot operated. A direct acting relief valve is held closed by the direct force of a mechanical spring. The spring force holding the valve closed is opposed by the system hydraulic pressure. The cracking pressure is the minimum pressure at which the valve will begin to open. This pressure is set by changing the tension in the spring using an adjusting nut or knob. As long as the system operates at a pressure at or under the cracking pressure, the valve remains closed. If the hydraulic pressure increases even a small amount beyond this level, the valve begins to open and fluid begins to trickle through. The pressure at which the valve is fully open is called the full relief valve pressure, and is higher than the cracking pressure. When the hydraulic fluid in the system reaches the full relief valve pressure, the valve will be fully open and all fluid is discharged through the outlet port.

A pilot-operated relief valve makes it possible to handle higher pressures and flow. It’s also much smaller than direct-acting valves rated for the same pressure. This valve has two stages. The first stage is composed of the main valve with the poppet and spring large enough to handle the maximum flow rating of the valve; the second stage is composed of a much smaller direct acting pilot valve, which includes a pilot relief poppet, pilot spring and an adjustment knob. This smaller relief valve is usually mounted crosswise on the main valve body. As long as pump line pressure is less than the relieving pressure set on the control knob, the pilot poppet will remain closed. Since the pilot poppet is closed, the pressure in the main spring chamber is the same as the line pressure. Since these pressures are equal, there is no pressure drop from one side to the other, and the main poppet also remains closed. When line pressure increases higher than the relieving pressure, the pilot relief valve moves to its open position. This allows fluid to flow from the pressure side through the orifice and across the pilot relief valve to the tank. Once the pilot valve is open, there is now a pressure drop across the main valve poppet with a higher pressure on the pump line side. This causes the main poppet to move allowing full flow through the relief valve. The same is true in reverse as the pump line pressure decreases below the relief pressure set by the adjustment knob, the pilot valve will close. This allows the main spool to close and restores a balance of pressure.

Applications of Different Pressure Relief Valve

Relief valves can be used anywhere in a hydraulic circuit where it’s necessary to prevent pressure from exceeding a maximum level. Advantages of direct acting valves are their low cost and fast response times to pressure spikes. Pilot-operated relief valves are advantageous due to their smaller size and ability to work with higher system pressures and higher flows.

Please visit http://www.adamantvalves.com/ for more information.

One Comment

Sonal Kumar

Wonderful such useful blog shared really helpful keep updating more thanks for it