Sanitary diaphragm valve is a special form of cut-off valve. It’s opening and closing parts is a diaphragm made of soft material to separate the inner chamber of the valve body from the inner cavity of the cover and the driving parts. Sanitary diaphragm valve is widely used in hygienic winemaking, dairy products, beverages, and other food industry as well as the pharmaceutical field of aseptic conditions, to achieve the control of pipeline fluid and open/close tasks.

Related: Sanitary diaphragm valve new products: Sanitary Diaphragm Bleed Valve With Tri-clamp Ends, Manual Type

Operation principle of sanitary diaphragm valve

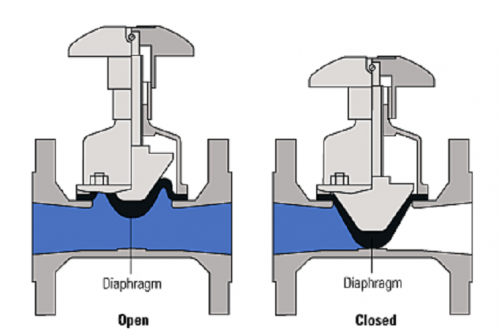

Diaphragm valves are normally closed with the diaphragm close to the inner chamber of the valve body and closing the pipeline flow path. When the diaphragm valve needs to perform cleaning or opening tasks, it is necessary to manually rotate the hand wheel or drive the pneumatic control actuator to drive the stem upward movement of the spherical diaphragm will be followed by upward bending, so as to make the valve into a conduction state.

The diaphragm separates the inner cavity of the lower valve body from the inner cavity of the upper cover so that the stem, spool and other parts located in the upper part of the diaphragm are not subject to the corrosion of the medium. This not only saves the packing seal structure and will not produce the medium leakage, and the optimized valve body design will also make the cleaning fluid completely excreted and will not cause the retention.

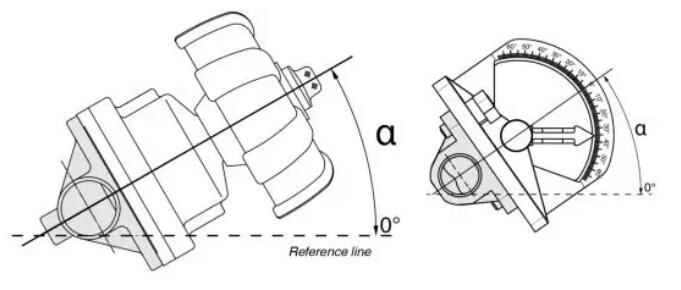

Mounting Angle of the valve body

The sealing edge of the sanitary diaphragm valve must be separated from the media, which is challenging for the horizontal pipe installation system. For this reason, the diaphragm valve needs to rotate axially (emptying Angle) until the point furthest from the center of the seal edge is aligned with the lowest point of the pipe connection. In this way, the medium can pass through the valve unimpeded under low-pressure drop and valve open state.

Fields of application

Sanitary diaphragm valve adopts reinforced silicone rubber, the valve body of which through high-speed finishing polishing and the smoothness reaches Ra0.2μm, so it is widely used in biological, pharmaceutical, food, electronic systems with high requirements for aseptic. Actually, the sanitary diaphragm valve is the most reliable product in the field of biological pharmacy. All kinds of mediums are made according to special requirements, and they are smooth and free from contact, dead Angle, absolute high cleanliness and complete quality assurance system. Therefore, it is widely used in the field of biological pharmacy and the system with high aseptic requirements such as water for injection, which is specially designed for GMP requirements.

The original article was published on Adamant Valves: http://www.adamantvalves.com/blog/what-should-you-know-about-sanitary-diaphragm-valves.html.

For more information, please visit http://www.adamantvalves.com/.

One Comment

Pingback: