The switch control of the Sanitary Pneumatic Ball Valves is a top priority. This affects a series of production of sanitary valve production and transportation. The valve should be sealed and pressure tested. If the valve switch can be used normally, and there is no leakage during the pressure test, the valve is qualified.

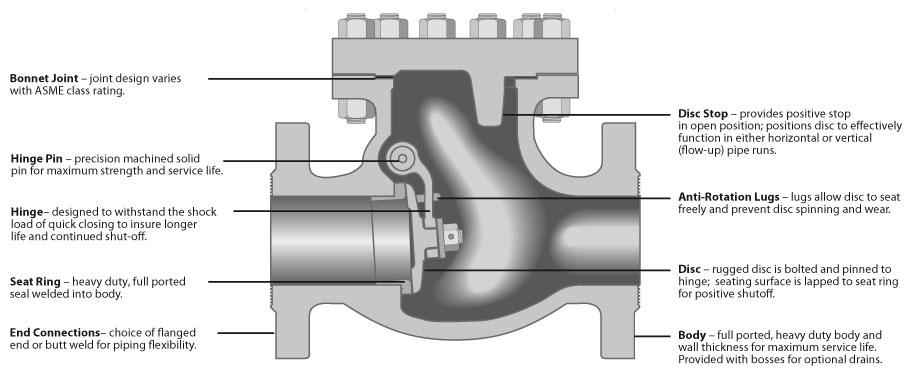

The valve is the control component of the fluid line. The body, disc and sealing surface of the valve need to meet the corresponding requirements in order to avoid corrosion. Generally speaking, the requirements for valve strength are mainly considered from the various conditions of temperature, corrosivity and pressure of the medium.

When the valve is opened and closed, the water hammer effect will occur. Although the impact damage to the valve is small, the damage to the fluid pipeline is relatively large. Therefore, the producer needs to consider the occurrence and response of the problem when producing the valve

Leakage is mainly divided into internal leakage and external leakage. The external leakage is mainly caused by improper installation. Therefore, workers are required to install the valve according to the installation requirements to avoid leakage. The internal leakage is mainly caused by the tight sealing of the valve, and can be divided into two aspects: the production is not up to standard and the installation is not correct. Sometimes the valve is used for too long, and there will be leakage. In this case, it can be repaired by a wrench. The video below may help you save time and money to change a valve.

Adamant Valves is a professional sanitary valves manufacturer. If you are interested, please visit our website http://www.adamantvalves.com/ for more information.