A sampling valve is a valve used to take a sample of a medium in a pipeline or equipment. It can be used in many cases where chemical analysis of media samples is required. Here is how most sample valve works:

According to the working principle or performance in the sampling process, the sampling valves are mainly divided into four types, including double opening valves, flange clip valves, sampling valves with thermal insulation jackets and aseptic sampling valve.

Double open valve

The double open valve is a more common sampling valve characterized by safe and stable sampling. It is usually composed of two connected ball valves. Sampling process: first close the A valve in the double open valve close to the equipment and pipeline; then open the B valve, let the medium flow into the space between the two valves; close the B valve and open the A valve; place the sampling vessel at the sampling port to hold the sampling medium.

Flange clip valve

The principle of the flange clip valve is to seal through the vertebral body at the top of the valve stem and the taper hole of the valve seat. When sampling, use the position of the hand wheel to lift the valve stem to separate the valve stem from the taper hole. The media can flow into an external sampling vessel.

Sampling valve with an insulated jacket

During the use of the sampling valve, if it is necessary to use the insulation jacket, it should be noted that during operation, the valve cannot be forcibly opened before the medium is completely melted. It is necessary to wait until the crystallization in the valve melts before opening the valve, otherwise, it is easy to cause a safety accident. When using the sampling valve with an insulated jacket, it should be noted that the valve cannot be forcibly opened. If the valve cannot be opened, avoid using the extension arm, which will cause the valve to be overstressed and cause the valve core and the stem to fall off, or cause damage to the sampled parts, resulting in a safety hazard.

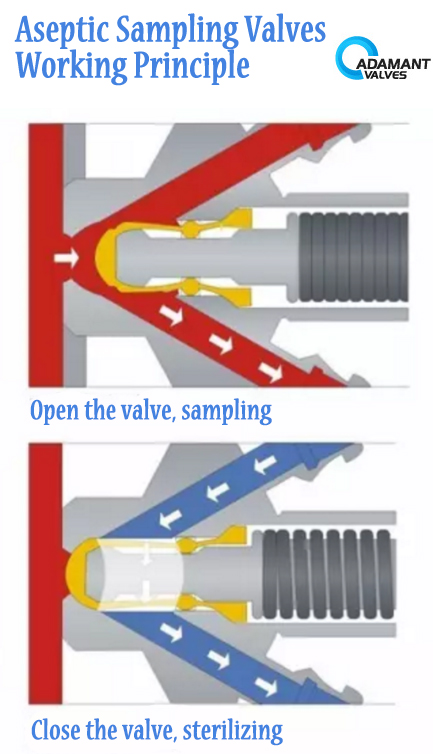

Aseptic sampling valve

The aseptic sampling valve is a special valve used for sterilization and disinfection before and after each sampling operation, and is suitable for the industrial chain with extremely high hygiene requirements.

The structure of the aseptic sampling valve mainly includes the sealing rubber sleeve, the storage chamber, the sampling port, the stainless steel thimble, the spring, the thimble sleeve, the manual knob (the difference between the automatic aseptic sampling valve and the manual is whether or not the pneumatic device is used).

Its basic working principle is that when it is closed, the thimble is pushed by the spring tension or other pressure, and the sealing head is pressed by the thimble to the opening of the tank wall to seal. When sampling is required, introduce steam or other sterilizing medium into one of the sampling ports, and the entire sample chamber is filled with steam and is discharged from the other sampling port. After a certain period of time, the reservoir and sampling port are sterile. Then release the thimble by twisting the knob and retracting the spring to disengage the sealant from the opening in the can wall, so that the sample flows out of the can through the sample chamber and is collected from the sampling port. After the sampling is completed, turn the knob to loosen the spring, and press the sealing head again by the thimble at the opening of the tank wall.

Adamant’s AV-7A stainless steel aseptic sampling valves and AV-7PA Pneumatic Type Aseptic Sampling Valves are used in the food, dairy, brewery, winery and many other hygienic industries. Please visit http://www.adamantvalves.com for more information.