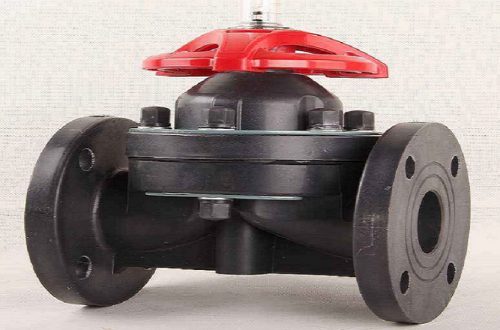

Sanitary safety air pressure relief valve is a valve mechanism for the automatic release of a substance from a boiler, pressure vessel, or other systems when the pressure or temperature exceeds preset limits.

Containers used in the following situations must be fitted with safety valves:

1. An independent pressure system (with a shut-off valve separated from other systems) needs to install a safety valve. The system refers to all gas phase, all liquid phase or gas phase communication;

2. When there is no safety valve at the source of the pressure material of the container, the container must be equipped with a safety valve;

3. Containers and pipelines whose design pressure is lower than the pressure at the source of pressure;

4. The outlet pipes of positive displacement pumps and compressors need to be installed with safety valves;

5. Containers with overpressure due to the accumulation of non-condensable gas must be equipped with safety valves;

6. If there is a shut-off valve or a control valve on the outlet pipeline of the heating furnace, a safety valve should be installed upstream of the valve;

7. Safety valves need to be installed at overpressure parts caused by process accidents, automatic control accidents, power accidents, fire accidents and public works accidents;

8. A safety valve should be installed in the part where the thermal expansion of the liquid occurs due to the closure of the valves at both ends;

9. A safety valve can be placed in the steam outlet pipeline of the condensing turbine;

10. In some cases, due to the leakage of the check valve at the pump outlet, a safety valve is set on the inlet pipe of the pump.

For more information, please visit https://www.adamantvalves.com/.