From the food industry to the medical industry, and from milk to pharmaceuticals, sanitary valves and sanitary fittings provide security for multiple industries that serve millions of people every day. These sanitary devices help ensure that the products people get are of high-quality and safety, so they are of great importance. Today we’ll focus on the medical application of sanitary valves. In recent years, the medical industry has developed many new technologies using cellular and biomolecular processes to help improve the lives of people around the earth and the health of the planet itself. The main goals of the medical industry are to heal the world, power the world, and…

-

-

3 Major Anti-corrosion Methods for Sanitary Valves

We all know that strong corrosion resistance is one of the important features of sanitary valves. Today we will talk about the three major anti-corrosion methods for sanitary valves. Surface Coating The surface coating is the most widely used method of corrosion protection. It is an indispensable anti-corrosion material and identification mark for sanitary valves. The coating used for valves is usually made of synthetic resin, rubber slurry, vegetable oil and solvent. They are applied to the valve surface to insulate the medium and the atmosphere for corrosion protection. The above coatings are mainly used in less corrosive water, salt water, sea water or the atmosphere. Corrosion inhibitor Corrosion inhibitors…

-

Sanitary Valves Used in the Drink Industry

We have always talked about that sanitary valves are important for food and drink industries, but we never detailed into it. Thus, today let’s talk about the importance of sanitary valve and sanitary fitting in the drink industry. Perfect Solutions For Drink Production In The U.S. The drink industry is one of the main industries that we work with is. It is a fact that everybody has to drink every day, and reality is that the standard of drink production in the United States is extremely high. Ordinary valves will accumulate a lot of harmful substances such as bacteria and microorganisms in the production process, which is absolutely not allowed…

-

What are sanitary fittings?

Sanitary fittings were well developed and are widely used because they are cleanable; either by dismantling a system and manually cleaning it or using a CIP (clean in place) process. They limit entrapment areas where bacteria could form or harbor. They are also corrosion resistant. Additionally, sanitary fittings do not contain any pockets, threading, or tight bends. This design specification is meant to eliminate the areas that are difficult to clean. Occasionally materials being processed will interact with stainless steel, potentially causing them to corrode and eventually fail. For this reason, sanitary fittings are available in specific stainless steel alloys to make sure they can handle more demanding processing environments.…

-

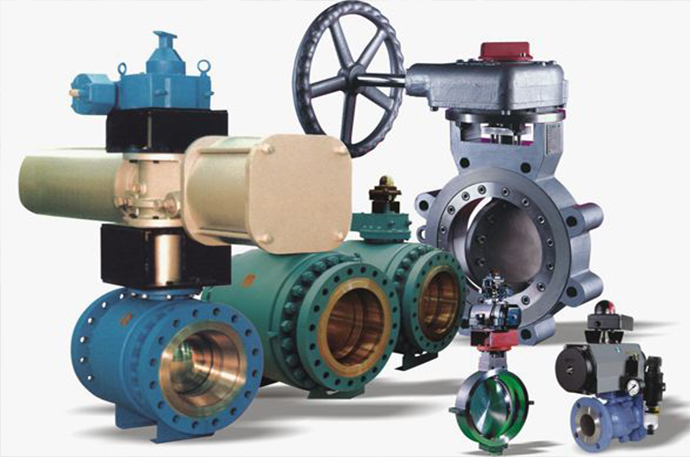

Why Choosing Sanitary Valve Rather Than Industrial Valve

A valve is a device that regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or slurries) by opening, closing, or partially obstructing various passageways. Currently, most valves in the market are industrial valves, but sanitary valves do have their own advantages in some specific industries. Read on and find the difference between these two types of valves. As the name implies, the sanitary valves refer to those which meet the health standards, food standard and medical standard. The valve body shall meet the hygienic standard of stainless steel and all contact parts with the medium shall be mirror polished, both polishing and cleanliness are subject…