Similarly with ordinary valves, sanitary valves can be categorized into sanitary sanitary butterfly valve, ball valve, sanitary check valve and so on. Sanitary butterfly valve Sanitary butterfly valve is a special type of sanitary valve because of its charming name. It gets its name due to its similar appearance with the butterfly. The structure of sanitary valve is simple. It controls the flow by rotating about the axis in the cylindrical passage of the butterfly valve body. When the disc reaches 90°, the valve is fully open; and when the disc reaches 0°, the valve is closed. Sanitary ball valve Sanitary ball valve is a common type in our life…

-

-

Categories of pressure relief valves and their applications

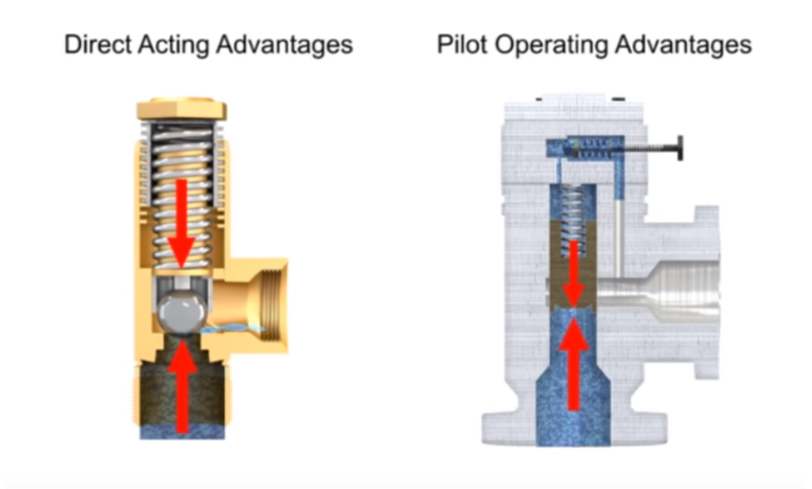

Importance of Pressure Relief Valve The Pressure Relief Valve is one of the most important types of safety valves. This type of valve sets a limit on the rise of pressure within a hydraulic line. In normal operations, the valve is closed and no fluid passes through; but if the pressure in the line exceeds the limit, the valve opens to relieve the pressure. This protects expensive machinery such as motors pumps and actuators from becoming damaged from high-pressure. Without a relief valve, the pressure can continue to grow until another component fails and pressure is released. Categories of Pressure Relief Valve Pressure relief valves fall into two categories: direct…

-

An overview of Diaphragm Valves

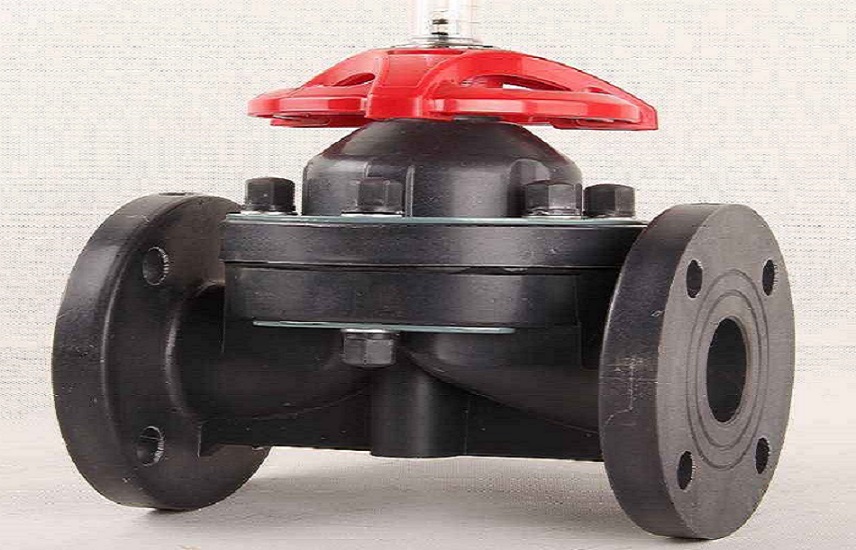

The diaphragm valve, structurally different from the general valve, is a special type of shut-off valve. Its opening and closing member is a diaphragm made of soft material (elastic, corrosion-resistant, non-permeable material such as rubber and plastic), which separates the valve body cavity from the bonnet cavity and the driving member. Diaphragm valves can be used for low pressure, low temperature, corrosive and suspended materials. They have the advantage of simple structure, good sealing and anti-corrosion performance, and low fluid resistance, so it is widely used in various fields. Diaphragm Valve Classification -According to the structure, there are ridge type, cut-off type, ram type, etc.; -According to the driving method,…

-

Application and development of ceramic valves

What is Ceramic Valve Ceramics are characterized by heat resistance, corrosion resistance, wear resistance, high hardness, low temperature deformation and high sealing surface precision. The use of ceramic properties as a valve manufacturing material has broad prospects. In recent years, a variety of ceramic materials have been used in the manufacture of valves. Ceramic valves generally use ceramics to make the components, or add a ceramic coating on the metal surface. Types and Application of Ceramic Valve 1 ceramic ball valve Ball valves can be used as flow control valves or shut-off valves for corrosive fluids and high-temperature fluids containing solid materials. Depending on the application, you can choose valves…

-

How to choose the different steel materials of sanitary valves?

Nowadays, 304 and 316 stainless steel are the two most popular materials for making sanitary valves. For normal customers who are not very familiar with the sanitary valve materials, 304 steel and 316 steel are just different in their “numbers”. But the difference between them can be huge. Please read on to know which kind of sanitary valve material to choose. Usually, stainless steel products contain a mixture of elements including: Chromium, Nickel, Carbon and Manganese. That accounts for why 304 stainless steel and 316 stainless steel look so similar. When it comes to the difference in their structure, 316 Stainless Steel has the same chemical composition as 304 steel…