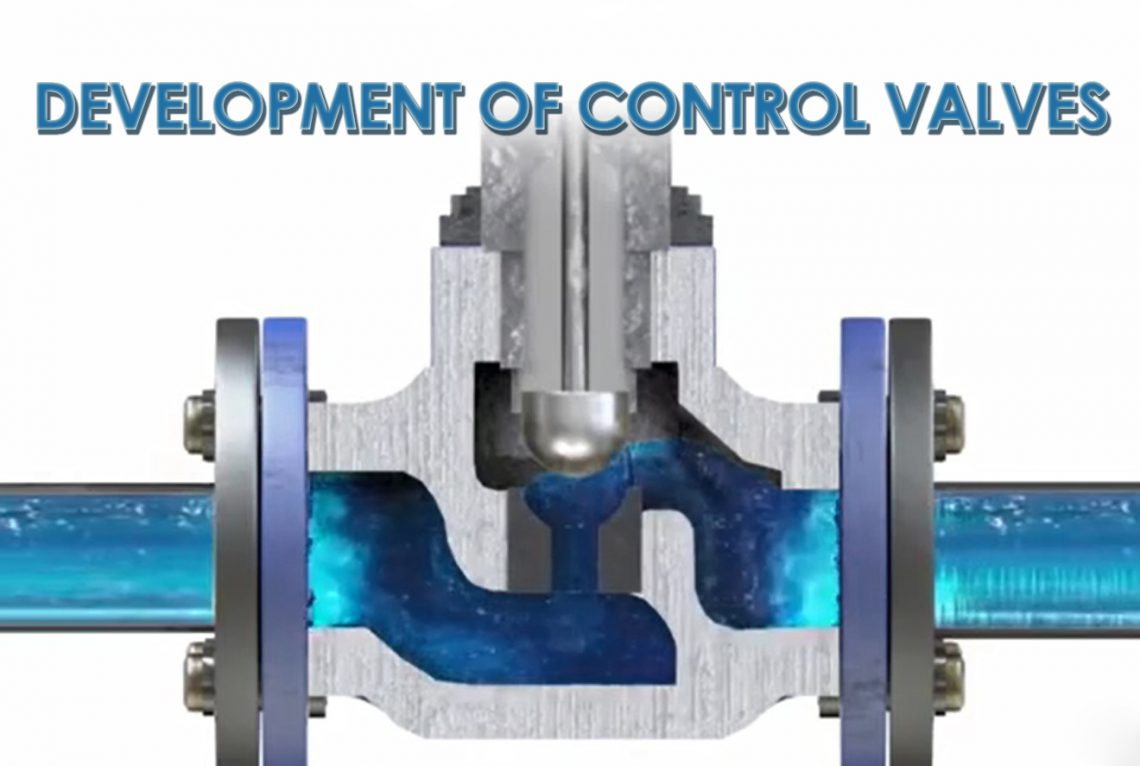

Regulating valve, or control valve, refers to a tool used in industrial production to adjust process parameters such as medium flow, pressure, temperature, liquid level, etc. In some automated production links, the opening of the valve can be automatically adjusted according to the control signal in the system, so as to realize the adjustment of medium flow, pressure, temperature, and liquid level. Development History Since the beginning of the 20th century, the development of control valves has produced ten categories of control valve products, self-operated valves and positioners. The specific timeline is as follows: The 1920s: The original regulating valve for pressure stabilization was introduced. The 1930s: The V-type regulating…

-

-

How to Select the Right Valve in Pipeline Design?

Valve Characteristics The use characteristics of the valve determine its main performance and use range. The use characteristics of the valve include: valve category (closed-circuit valve, regulating valve, safety valve, etc.), product type (gate valve, globe valve, butterfly valve, ball valve, etc.), valve main parts (valve body, valve cover, valve stem, valve disc, sealing surface) material, valve rotation method, etc. The structural characteristics of the valve determine the installation, repair, maintenance and other methods of the valve. The structural characteristics include: the structural length and overall height of the valve, the connection form with the pipeline (flange connection, threaded connection, clamp connection, external thread connection, welding end connection, etc.), the…

-

29 Construction Terminologies of Valves

Structure length The distance between the inlet and outlet end faces of the valve; or the distance from the inlet end face to the outlet axis. Structural length of straight-through valve The distance between two planes perpendicular to the valve axis at the ends of the valve body passage. Structural length of angle valve The distance between the plane perpendicular to the axis at one end of the valve body passage and the axis of the other end of the valve body. Type of construction The main features of various types of valves in terms of structure and geometry. Through way type The inlet and outlet axes are coincident or…

-

37 Basic Terminologies of Valves (A to Z)

1. Action sensitivity and reliability This refers to the sensitivity of the valve to respond to changes in medium parameters. Actuator 2. Wormgear actuator A device that uses a worm gear mechanism to open, close or adjust a valve. 3. Pneumatic actuator A pneumatic actuator is a drive device that opens, closes or adjusts the valve with air pressure. 4. Hydraulic actuator The drive device that opens, closes or adjusts the valve with hydraulic pressure. 5. Connection dimensions Dimensions of valve and pipe connections. 6. Disc A general term for a part used to cut off or regulate the flow of media, such as the gate in the gate valve,…

-

How to solve the problem of valve corrosion?

Valve corrosion refers to the destruction of metal materials by chemical or electrochemical reactions with their environment. How to isolate the metal from the surrounding environment or use non-metallic composite materials to control and prevent gradual corrosion of metal valves has become a common concern of people. Corrosion of metals has a considerable impact on the duration, reliability and service life of valves. During valve operation, the rubbing surfaces are worn and damaged as a result of the simultaneous mechanical action and chemical or electrochemical interaction of the metal with the environment. For valves, the climatic conditions of their pipelines are complex: the presence of hydrogen sulfide, carbon dioxide and…