Sanitary ball valves are also called as hygienic ball valve which is opened by turning handles attached to balls inside the valves. The ball has a hole or port through the middle. When the port is in line with both ends of the valve, flow will occur. When the valve is closed, the hole is perpendicular to the ends of the valve, and flow is blocked. A ball valve is durable and usually work to achieve perfect shutoff even after years of disuse. Working Principle of Sanitary Ball Valve The Ball valve uses a hollow, perforated and pivoting ball to control flow through it. The ball valve drives the valve handle to…

-

-

7 Points of Pneumatic Butterfly Valve Maintenance

1. The pneumatic butterfly valve should be kept clean during use, and the transmission threads must be regularly lubricated. When a fault is found, it should be stopped immediately to find out the cause and clear the fault. 2. Packing gland bolts should be evenly tightened, and should not be crooked, so as to avoid injury to prevent stem movement or cause leakage. 3. During installation, the valve can be directly installed on the pipeline according to the connection method. Under normal circumstances, it can be installed at any position in the pipeline, but it needs to be easily accessible for maintenance. Note that the medium flow of the shut-off…

-

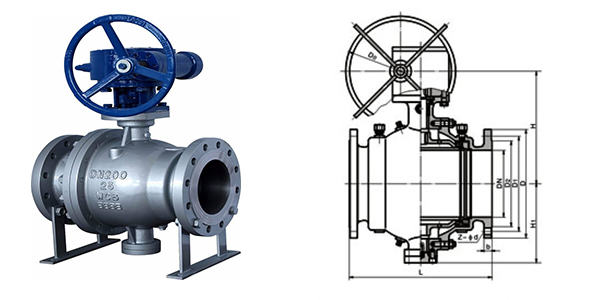

Classification of Ball Valves by Their Structural Types

Floating ball valve The sphere of the ball valve floats. Under the effect of medium pressure, the sphere can produce a certain displacement and be pressed tight on the sealing surface at the outlet, ensuring the sealing of the outlet. The floating ball valve has a simple structure and good sealing, but a load of working medium sustained by the sphere is all passed on to the outlet sealing ring. Therefore, one needs to consider if the material of the sealing ring can sustain the working load of the sphere medium. This structure is widely used in medium and low-pressure ball valves. Fixed ball valve The sphere of the ball…

-

Ceramic valves have excellent characteristics

At present, the valves commonly used in most industries are metal valves. The use of metal valves has been around for hundreds of years. Although it has been improved by structure and materials, it is more and more unable to adapt to the needs of harsh conditions such as high wear and strong corrosion due to the limitations of metal materials. The shortcomings of the traditional metal industrial valves are mainly reflected in the short service life and serious leakage, which greatly affects the stability of the system operation. These valves are in urgent need of radical innovation in materials, design and manufacturing processes. As a new material in the…

-

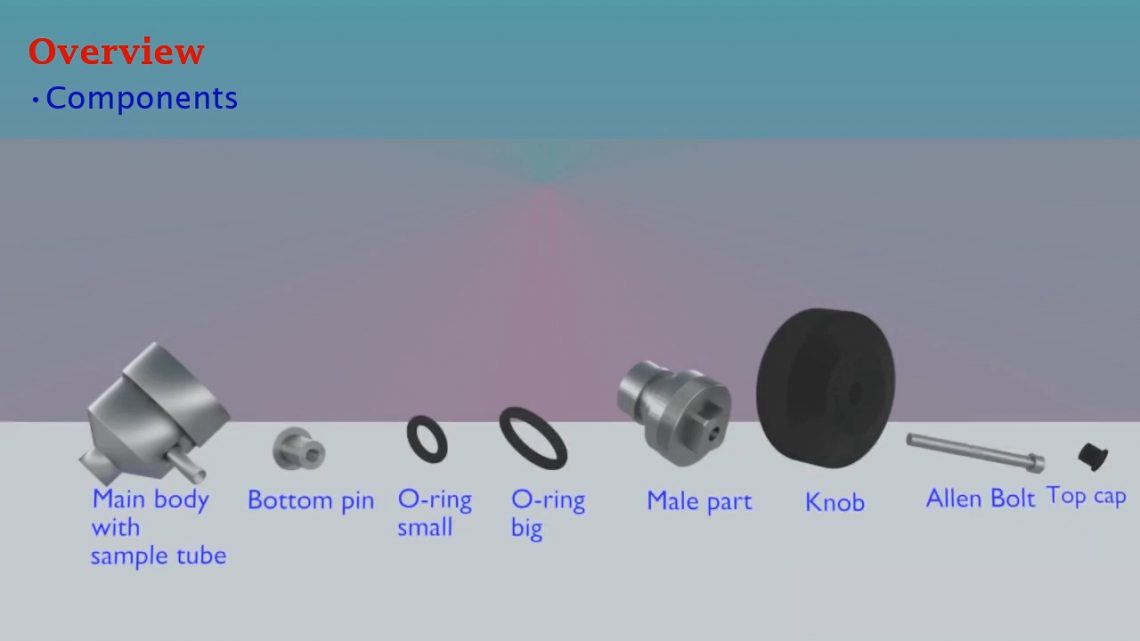

Sanitary Sample Valve Classification, Components and Assembly

The sanitary sampling valve is a valve used to obtain a sample of the medium in the pipeline or equipment. In many cases where chemical analysis of the medium is often required, a special sampling valve is often used. Sanitary Sample Valve Classification According to the working principle or performance at the time of sampling, the sampling valves are mainly divided into three types, including double opening valves, flange clamping valves and sampling valves with thermal insulation jackets. Double opening valve The double opening valve is a more common sampling valve, usually composed of two connected ball valves, which are characterized by safe and stable sampling. During the sampling process,…