The production of valves is a complex yet simple process. The production cycle of ordinary valves such as gate valves, ball valves, globe valves, butterfly valves and check valves is generally three days. After the valve is produced, it must undergo various performance tests, the most important of which is the pressure test. The pressure test is to test whether the pressure value that the valve can withstand meets the requirements of production regulations. The following are the precautions for valve pressure testing in general: (1) In general, the valve is not tested for strength unless the valve body and bonnet are repaired or corroded. For the safety valve, its…

-

-

Precautions for Using Electric Emergency Shut-off Valve

Electric emergency shut-off valves are generally used on various water pipes and air pipes to prevent leakage. When you think the flow rate of water or airflow is too high or too low, you can use an electric emergency shut-off valve to close and open the valve, so that the fluid flows through the pipeline at a uniform flow rate. So, what aspects should be paid attention to when using the electric emergency shut-off valve? Read on to find answers to the question. 1. Store the valve in a dry place It is very important to prepare a good storage space. When the valve is placed in a humid environment,…

-

Different Types of Fluid Valves and Their Characteristics

Valves are pipeline accessories used to open and close pipelines, control the flow direction, and adjust and control the parameters (temperature, pressure and flow) of the conveying medium. They play a pivotal role. Let’s take a look at different types of fluid valves and their characteristics. Ball Valve Ball valves are available in two designs, float and trunnion. The floating ball valve will generate high operating torque at high pressure or large pipe diameter, but the sealing performance is better. Ball valves are not suitable for throttling because, when the valve is partially open, its sealing surfaces are damaged by exposure to the process fluid. For critical operations, consideration should…

-

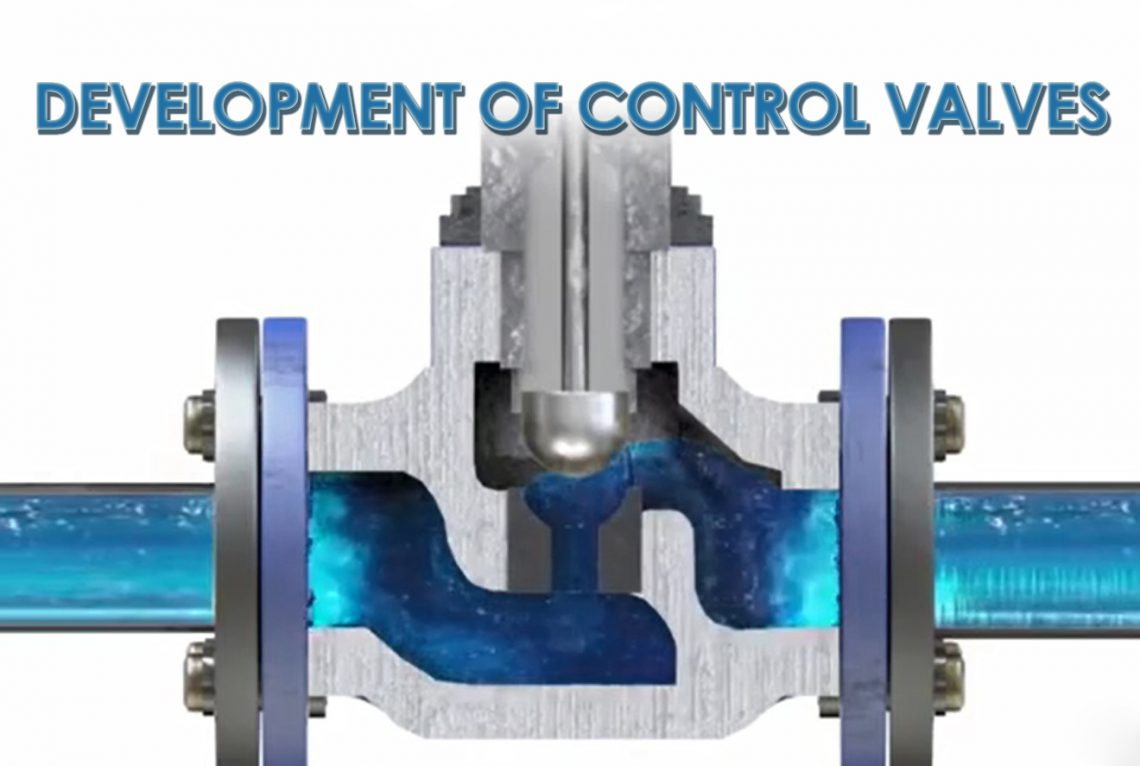

Development of Control Valves

Regulating valve, or control valve, refers to a tool used in industrial production to adjust process parameters such as medium flow, pressure, temperature, liquid level, etc. In some automated production links, the opening of the valve can be automatically adjusted according to the control signal in the system, so as to realize the adjustment of medium flow, pressure, temperature, and liquid level. Development History Since the beginning of the 20th century, the development of control valves has produced ten categories of control valve products, self-operated valves and positioners. The specific timeline is as follows: The 1920s: The original regulating valve for pressure stabilization was introduced. The 1930s: The V-type regulating…

-

How to Select the Right Valve in Pipeline Design?

Valve Characteristics The use characteristics of the valve determine its main performance and use range. The use characteristics of the valve include: valve category (closed-circuit valve, regulating valve, safety valve, etc.), product type (gate valve, globe valve, butterfly valve, ball valve, etc.), valve main parts (valve body, valve cover, valve stem, valve disc, sealing surface) material, valve rotation method, etc. The structural characteristics of the valve determine the installation, repair, maintenance and other methods of the valve. The structural characteristics include: the structural length and overall height of the valve, the connection form with the pipeline (flange connection, threaded connection, clamp connection, external thread connection, welding end connection, etc.), the…