1. Action sensitivity and reliability This refers to the sensitivity of the valve to respond to changes in medium parameters. Actuator 2. Wormgear actuator A device that uses a worm gear mechanism to open, close or adjust a valve. 3. Pneumatic actuator A pneumatic actuator is a drive device that opens, closes or adjusts the valve with air pressure. 4. Hydraulic actuator The drive device that opens, closes or adjusts the valve with hydraulic pressure. 5. Connection dimensions Dimensions of valve and pipe connections. 6. Disc A general term for a part used to cut off or regulate the flow of media, such as the gate in the gate valve,…

-

-

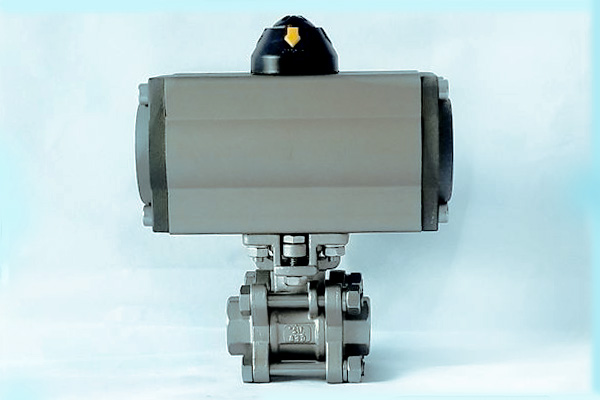

Pneumatic Ball Valve VS Pneumatic Butterfly Valve

A pneumatic ball valve uses a sphere around the axis of the stem that rotates 90 ° to realize the function of open and closed. A pneumatic ball valve in the pipeline is mainly used to cut off, distribute and change the direction of medium flow, and the design of a v-shaped opening pneumatic ball valve also has a good flow regulation function. Different from the pneumatic ball valve, a pneumatic butterfly valve is a valve that uses disc-type opening and closing of a reciprocating swing around 90 ° to open, close, and adjust the fluid channel. Pneumatic ball valve Obstruction and secretion obstruction and secretion When the ball valve…

-

Control System, General Requirements and Working Principle of Pneumatic Sanitary Valve

General Requirements for Pneumatic Sanitary Valves The specifications and categories of the production of pneumatic sanitary valves shall meet the requirements of pipeline design documents. The model of the pneumatic valve should indicate the national standard number requirements. If it is manufactured according to enterprise standards, the relevant description of the model should be indicated. The working pressure of the pneumatic sanitary valve is greater than or equal to the working pressure of the pipeline, and without affecting the price, the working pressure that the valve can withstand should be greater than the actual working pressure of the pipeline; either side of the pneumatic valve should be able to withstand…

-

7 Points of Pneumatic Butterfly Valve Maintenance

1. The pneumatic butterfly valve should be kept clean during use, and the transmission threads must be regularly lubricated. When a fault is found, it should be stopped immediately to find out the cause and clear the fault. 2. Packing gland bolts should be evenly tightened, and should not be crooked, so as to avoid injury to prevent stem movement or cause leakage. 3. During installation, the valve can be directly installed on the pipeline according to the connection method. Under normal circumstances, it can be installed at any position in the pipeline, but it needs to be easily accessible for maintenance. Note that the medium flow of the shut-off…

-

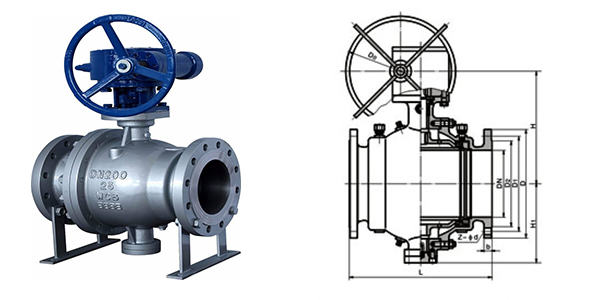

Classification of Ball Valves by Their Structural Types

Floating ball valve The sphere of the ball valve floats. Under the effect of medium pressure, the sphere can produce a certain displacement and be pressed tight on the sealing surface at the outlet, ensuring the sealing of the outlet. The floating ball valve has a simple structure and good sealing, but a load of working medium sustained by the sphere is all passed on to the outlet sealing ring. Therefore, one needs to consider if the material of the sealing ring can sustain the working load of the sphere medium. This structure is widely used in medium and low-pressure ball valves. Fixed ball valve The sphere of the ball…