Sanitary valves are used in higher hygiene requirements occasions. It seems to have no difference compared with the industrial valves only from their appearances. In other words, the difference between sanitary valves and industrial valves is not obvious in some ways. Here’s a comparison. The biggest difference between the two valves is the raw materials used to manufacture them. Sanitary valves are used in the environment of high hygiene requirements such as pharmaceutical, food and daily commodities. These products are edible or having direct contact with human bodies. Therefore, there is high sanitation demand for the manufacturing machinery, and ordinary steel, iron, copper and other materials cannot meet the standard. For…

-

-

An Overview of Sanitary Control Valve

Control valves regulate the flow of liquids, gases, or a mixture of both as required. In its most basic form, a control valve has an adjustable aperture which is opened and closed manually as necessary—opening to increase the flow and closing to decrease the flow. Why do we need control valves? In many cases, the piping system requires a precise amount of constant flow to properly determine the size of the pump, piping and other accessories. If there is no proper flow control valve, the fluctuating system pressure will deviate from the design flow. The flow control valve should be constant. All valves in the system can be added together to help…

-

Why Choosing Sanitary Valve Rather Than Industrial Valve

A valve is a device that regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or slurries) by opening, closing, or partially obstructing various passageways. Currently, most valves in the market are industrial valves, but sanitary valves do have their own advantages in some specific industries. Read on and find the difference between these two types of valves. As the name implies, the sanitary valves refer to those which meet the health standards, food standard and medical standard. The valve body shall meet the hygienic standard of stainless steel and all contact parts with the medium shall be mirror polished, both polishing and cleanliness are subject…

-

Two Basic Types of Butterfly Valve: Lug & Wafer

About butterfly valve Butterfly valves have been around for a long time and have been used more and more widely in various industries since the 1930s when they first came out. Butterfly valves are usually made of cast iron and their name is based on the function of their discs. There are several different types of butterfly valves, but there are always two basic types of butterfly valves — lug and wafer. Butterfly valves are classified as “quarter turn” valves. The valve can be opened or closed by rotating the metal disk of the butterfly valve a quarter turn. When the butterfly valve is fully open, the fluid is allowed…

-

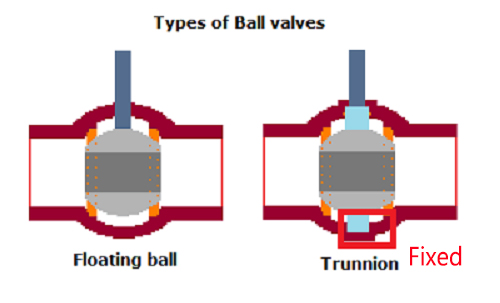

Comparison between floating ball valve and Trunnion ball valve

What is a ball valve? A ball valve is a one-way valve that is opened and closed by pressure on a ball which fits into a cup-shaped opening. Generally, a ball valve has two entries, but there is also 3-way ball valve, as shown below. A 3-way ball valve has three entries. It may have an L or a T design as shown in the picture below. Depending on your own requirement, you can arrange the entries of the 3-way ball valve in the following three-way. 1. One inlet and two distribute 2. One inlet and one outlet with diverting a flow 3. Straight pass the fluid without No inlet…