Gate Valve The gate valve is one of the most commonly used on-off valves that utilizes the gate to turn on (fully open) and cut off (fully closed) the media in the pipeline. The gate is lifted and lowered in a plane perpendicular to the center line of the gate seat passage and cut the medium in the pipeline like a gate, so it is called a gate valve. This type of valve cannot be used for throttling. Feautures: 1. The flow resistance is small. The inner medium passage of the valve body is straight so the medium flows in a straight line and the flow resistance is thus small.…

-

-

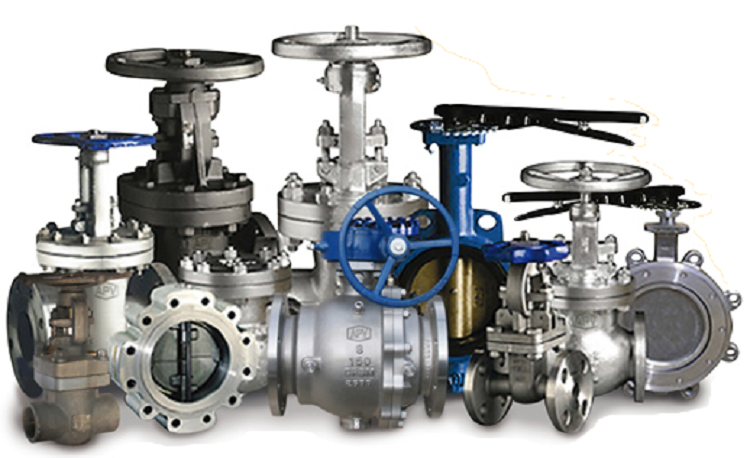

Types of Valve and Their Pros and Cons

Gate valve A gate valve is a valve that moves the closing member (gate) in the vertical direction of the channel axis. It is mainly used fully open or fully closed to shut off the medium in the pipeline. In general, gate valves are not available for regulated flow. It can be applied to low-temperature and low pressure or high temperature and high pressure, related to what kind of materials it is made of. However, gate valves are generally not used in pipelines for transporting media such as mud. Advantage 1 The fluid resistance is small; 2 The required torque for opening and closing is small; 3 can be used…

-

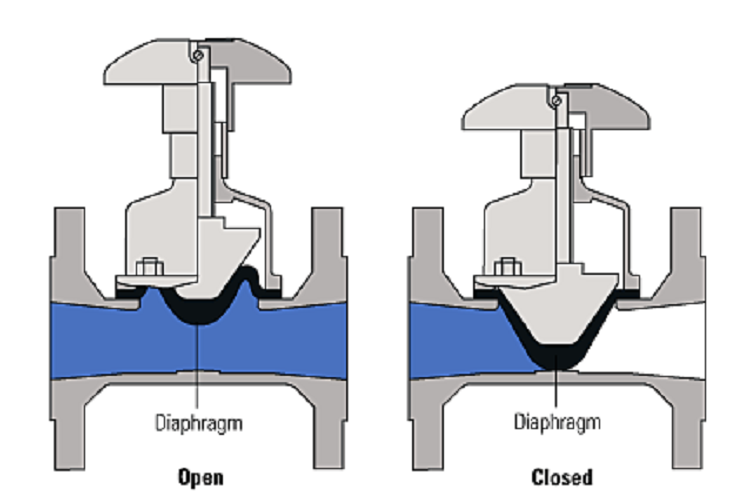

Pros and Cons of Diaphragm valve and Globe Valve

Diaphragm valve Diaphragm valves consists of a valve body with two or more ports, a diaphragm, and a “weir or saddle” or seat upon which the diaphragm closes the valve. The diaphragm valve was initially developed for industrial applications and pipe-organs. Later on the design was adapted for use in the bio-pharmaceutical industry by using compliant materials that can withstand sanitizing and sterilizing methods. What’s more, sanitary diaphragm valves are specially designed with the highest standard for applications in manufacturing of medicine and food. Diaphragm valves use a corrosion-resistant lining valve body and a corrosion-resistant diaphragm to replace the valve plug components, and control the medium by moving the diaphragm.…

-

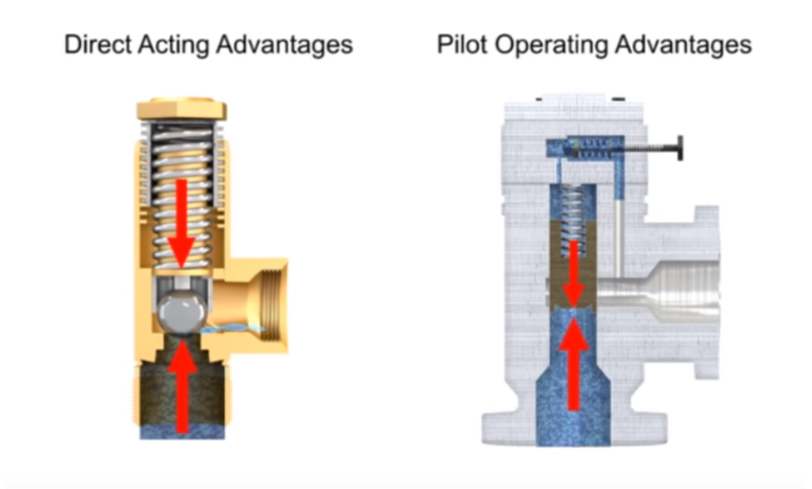

Categories of pressure relief valves and their applications

Importance of Pressure Relief Valve The Pressure Relief Valve is one of the most important types of safety valves. This type of valve sets a limit on the rise of pressure within a hydraulic line. In normal operations, the valve is closed and no fluid passes through; but if the pressure in the line exceeds the limit, the valve opens to relieve the pressure. This protects expensive machinery such as motors pumps and actuators from becoming damaged from high-pressure. Without a relief valve, the pressure can continue to grow until another component fails and pressure is released. Categories of Pressure Relief Valve Pressure relief valves fall into two categories: direct…

-

Application and development of ceramic valves

What is Ceramic Valve Ceramics are characterized by heat resistance, corrosion resistance, wear resistance, high hardness, low temperature deformation and high sealing surface precision. The use of ceramic properties as a valve manufacturing material has broad prospects. In recent years, a variety of ceramic materials have been used in the manufacture of valves. Ceramic valves generally use ceramics to make the components, or add a ceramic coating on the metal surface. Types and Application of Ceramic Valve 1 ceramic ball valve Ball valves can be used as flow control valves or shut-off valves for corrosive fluids and high-temperature fluids containing solid materials. Depending on the application, you can choose valves…