We all know that strong corrosion resistance is one of the important features of sanitary valves. Today we will talk about the three major anti-corrosion methods for sanitary valves. Surface Coating The surface coating is the most widely used method of corrosion protection. It is an indispensable anti-corrosion material and identification mark for sanitary valves. The coating used for valves is usually made of synthetic resin, rubber slurry, vegetable oil and solvent. They are applied to the valve surface to insulate the medium and the atmosphere for corrosion protection. The above coatings are mainly used in less corrosive water, salt water, sea water or the atmosphere. Corrosion inhibitor Corrosion inhibitors…

-

-

Sanitary Valves Used in the Drink Industry

We have always talked about that sanitary valves are important for food and drink industries, but we never detailed into it. Thus, today let’s talk about the importance of sanitary valve and sanitary fitting in the drink industry. Perfect Solutions For Drink Production In The U.S. The drink industry is one of the main industries that we work with is. It is a fact that everybody has to drink every day, and reality is that the standard of drink production in the United States is extremely high. Ordinary valves will accumulate a lot of harmful substances such as bacteria and microorganisms in the production process, which is absolutely not allowed…

-

Why Choosing Sanitary Valve Rather Than Industrial Valve

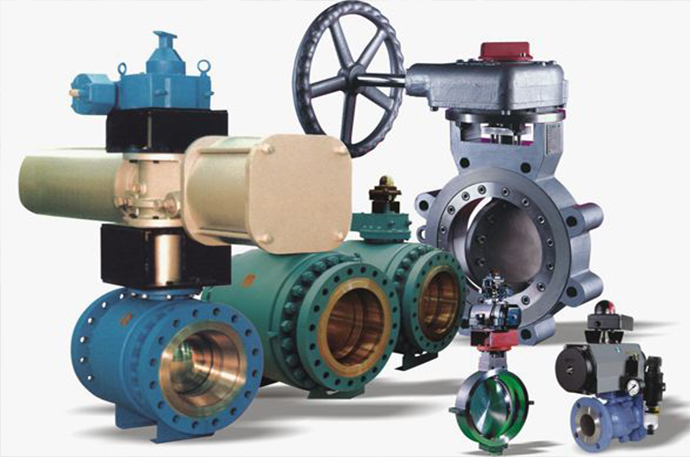

A valve is a device that regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or slurries) by opening, closing, or partially obstructing various passageways. Currently, most valves in the market are industrial valves, but sanitary valves do have their own advantages in some specific industries. Read on and find the difference between these two types of valves. As the name implies, the sanitary valves refer to those which meet the health standards, food standard and medical standard. The valve body shall meet the hygienic standard of stainless steel and all contact parts with the medium shall be mirror polished, both polishing and cleanliness are subject…

-

An Overview of Pumps

Pump Definition A pump is a device that moves fluid through mechanical action. Depending on the method used to move the fluid, the pumps can be divided into three main categories: direct lift, displacement and gravity pumps. Pumps have many sources of energy, including manual operation, electricity, electric motors or wind power; pumps are available in a variety of sizes, from micro sanitary pumps for medical applications to large pumps for industrial use. Pump types According to its displacement method, the pump can be divided into a positive displacement pump, an impulse pump, a velocity pump, a gravity pump, a steam pump and a valveless pump. The two basic types…

-

Sanitary Valves for Industrial Perfume Manufacturing

Perfume is one of our important cosmetics, both for women and men. It is a mixture of fragrant essential oils or aroma compounds, fixatives and solvents sprayed on the clothes, handkerchiefs or hairline to give a pleasant aroma. But do you have any idea about how the perfume is made? Generally, once the designers got the raw material they need for their perfume, they can start to make their perfume. The manufacturers distill the raw materials to get the essential oil and mix the essential oil with a designed percentage. Then, they need to add some alcohol products to ensure the high quality of the perfume. Perfume preparation in laboratory…