Valves are very common in our lives. If you add the word “sanitary” in front of the valve, do you really understand it? If your answer is NO, then just keep reading; if your answer is YES, then the next test is for you. Take the ball valve as an example. Would you think these are sanitary ball valves?

I believe most of you will answer “YES” again because the valves in the picture all contain three clip connections. However, the three-clip connection does not mean sanitary valves. So the answer is obvious now–these valves are just common valves with tri-clamp connections.

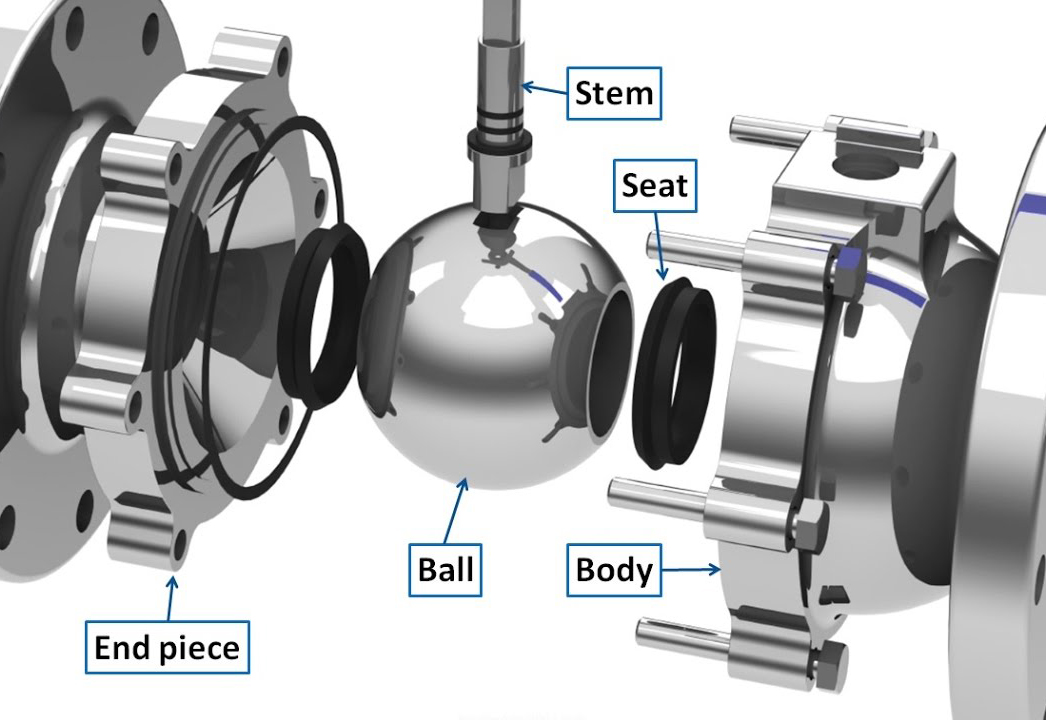

I don’t know how many people are right. Next, let’s take a look at the difference between a normal valve and a sanitary valve. A common ball valve has a dead space between the ball and the valve body. The flowing liquid may be trapped in the dead space of the valve to breed bacteria. And cleaning/sanitizing chemicals during the C.I.P. will not effectively clean and sanitize the valve. The following video well displays the process.

However, the sanitary valve has a higher manufacturing standard. The part of the valve that is in contact with the medium is usually made of 304SS or 316 stainless steel. The material is non-toxic and harmless with a smooth and clean surface, and it is not easy to cause corrosion or fall off. The high quality of sanitary valves makes them widely used in industries with high safety and sanitary requirements such as the food and medical industry.

Founded in 2002, Adamant Valves is a professional sanitary valve manufacturer specializing in manufacturing a wide range of sanitary butterfly valves and sanitary ball valves.

4 Comments

Pingback:

Pingback:

Pingback:

Pingback: