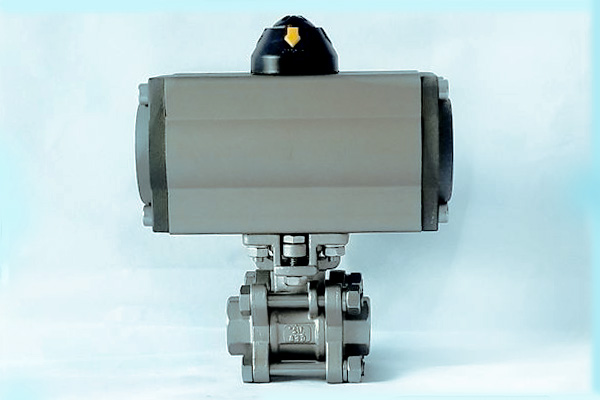

A pneumatic ball valve uses a sphere around the axis of the stem that rotates 90 ° to realize the function of open and closed. A pneumatic ball valve in the pipeline is mainly used to cut off, distribute and change the direction of medium flow, and the design of a v-shaped opening pneumatic ball valve also has a good flow regulation function.

Different from the pneumatic ball valve, a pneumatic butterfly valve is a valve that uses disc-type opening and closing of a reciprocating swing around 90 ° to open, close, and adjust the fluid channel.

Pneumatic ball valve

- Obstruction and secretion obstruction and secretion

When the ball valve is in a closed situation, the upper and lower side of the seat block the liquid, and the valve body cavity stagnation can be secreted by secreting equipment.

- Automatic pressure-relief structure

Temporary cavity pressure appears an abnormal phenomenon when adding the cavity medium can rely on its own thrust to push the seat and automatic pressure relief, and then ensure the safety of the valve lift.

- Reliable stem seal

The valve stem has the lower loading structure of the inverted seal, the sealing force of the inverted seal increases with the increase of medium pressure, so it can ensure the reliable sealing of the valve stem. Besides, the stem does not erupt when the stem is not pressurized properly.

- Antistatic construction

When operating a valve, a static charge is generated by friction between the ball and seat and accumulates on the ball. To prevent the occurrence of electrostatic spark, the valve is specially equipped with electrostatic equipment to export the accumulated charge on the sphere.

Pneumatic Butterfly Valve

The circular butterfly plate rolling with the valve is used for opening and closing so that the pneumatic valve in operation is mainly used for cutting off the valve. According to the structural characteristics of the pneumatic butterfly valve, it can also be planned to have the function of dispatching or segment valve concurrently dispatching. Now a variety of butterfly valves such as pneumatic butterfly valves, manual butterfly valves, sanitary butterfly valves, etc. in the use of low-pressure large and medium-sized diameter pipelines is increasing.