What is a check valve?

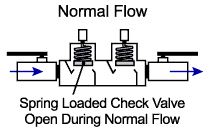

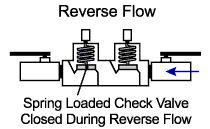

A check valve, or a one-way valve, is a valve that normally allows fluid (liquid or gas) to flow through it in only one direction. It is a type of two-port valves. In other words, it has two openings in the body, one for fluid to enter and the other for fluid to leave. There are various types of check valves used in a wide variety of applications. The check valve is available in a wide range of sizes and costs, check valves generally are very small, simple, or inexpensive. Check valve work automatically and most are not controlled by a person or any external control (there are some exceptions); accordingly, most do not have any valve handle or stem. The bodies (external shells) of most check valves are made of plastic or metal. Still, there are other available materials for making check valves. In some industries which have high requirements on the cleanliness of the fluid medium, sanitary check valves are preferred.

What is a double check valve?

A double check valve is a backflow prevention device designed to protect water supplies from contamination. It is also a valve used in air brake systems on heavy trucks. It consists of two check valves combined in series. There are two principles in the use of the double check valve employs:

1) Firstly, one check valve will still act, even if the other is jammed wide open.

2) Secondly, the closure of one valve reduces the pressure differential across the other, allowing a more reliable seal and avoiding even minor leakage.

The double check valve is suitable for prevention of back pressure and back siphonage, but is not suitable for high hazard applications. It is commonly used on lawn irrigation, fire sprinkler[1] and combi-boiler systems. If the hazard is higher, even a relatively low hazard such as using antifreeze in the fire sprinkler system, then a more reliable check valve such as a reduced pressure zone device may be mandated.

What is a sanitary double check valve?

The main difference between the sanitary double check valve and ordinary double check valve are the design and materials. A sanitary valve is designed for use in applications requiring clean or sterile processing. Sanitary valves are commonly used in dairy, food, pharmaceutical, medical, and chemical applications. Their common features include easy cleaning, crevice-free, and polished contact surfaces. The part of the valve in contact with the medium is usually made of 304SS or 316 stainless steel, which is non-toxic and is not easy to cause corrosion.

Please visit http://www.adamant-valves.com/ for more information.