The sanitary sampling valve is a valve used to obtain a sample of the medium in the pipeline or equipment. In many cases where chemical analysis of the medium is often required, a special sampling valve is often used.

Sanitary Sample Valve Classification

According to the working principle or performance at the time of sampling, the sampling valves are mainly divided into three types, including double opening valves, flange clamping valves and sampling valves with thermal insulation jackets.

Double opening valve

The double opening valve is a more common sampling valve, usually composed of two connected ball valves, which are characterized by safe and stable sampling. During the sampling process, first, close the A valve in the double opening valve close to the equipment and pipeline, then open the B valve, let the medium flow into the space between the two valves, then close the B valve, open the A valve, and place the sample vessel at the sampling port to hold the sampling medium.

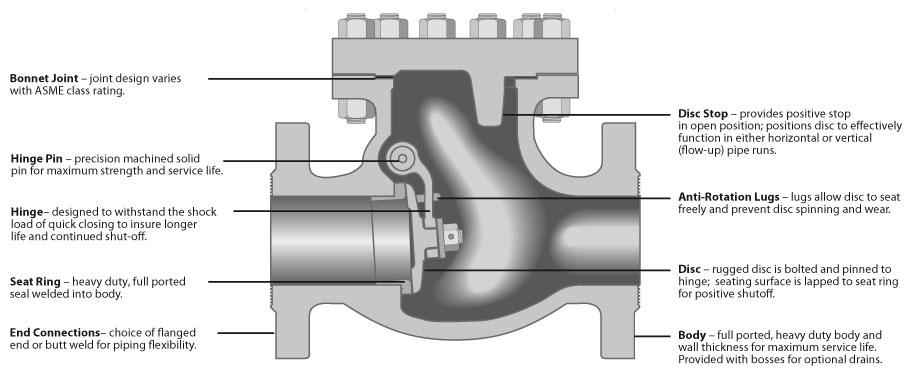

Flange clip valve

The principle of the flange clip valve is to seal through the vertebral body at the top of the valve stem and the taper hole of the valve seat. When sampling, use the position of the handwheel to lift the valve stem to separate the valve stem from the taper hole. The media can flow into an external sampling vessel.

Sampling valve with an insulated jacket

During the use of the sampling valve, if it is necessary to use the insulation jacket, it should be noted that during operation, the valve cannot be forcibly opened before the medium is completely melted; the valve must be opened after the crystal is dissolved in the valve, otherwise, it is easy to cause security incident.

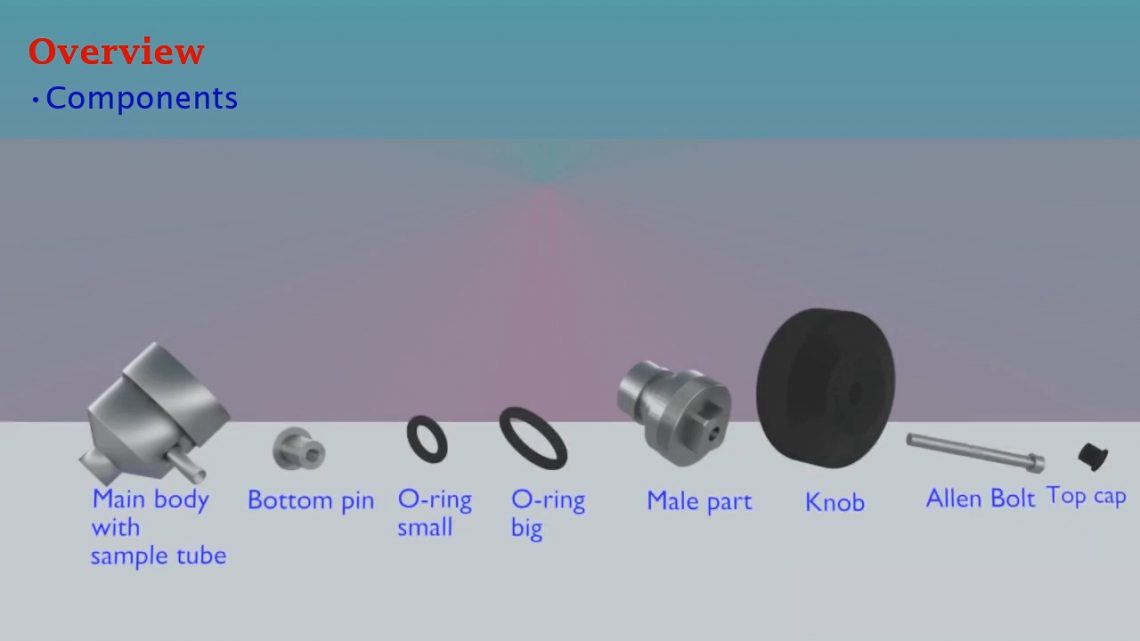

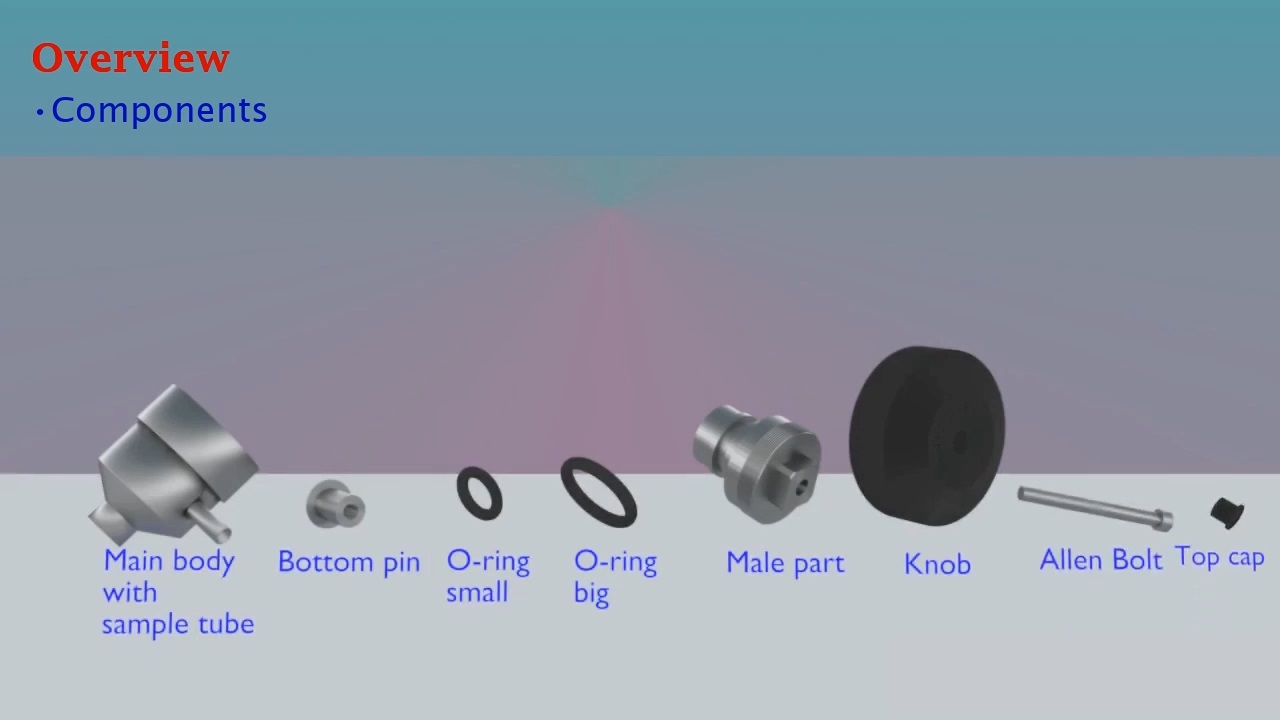

Sanitary Sample Valve Components

Sanitary Sample Valve Assembly

Adamant Valves is a global sanitary valves manufacturer and valves supplier. For more information, please visit https://www.adamantvalves.com/.